RESTORATION OF A CLOCK TOWER

We recently had an opportunity to retro-fit a set of 3 5’ tower clocks for the City of Hudsonville. The City was tired of the time-setting difficulties, poor illumination and the need to call a sign company for the frequent service.

We proposed our typical arrangement for modern tower clocks :

New Clock Movement

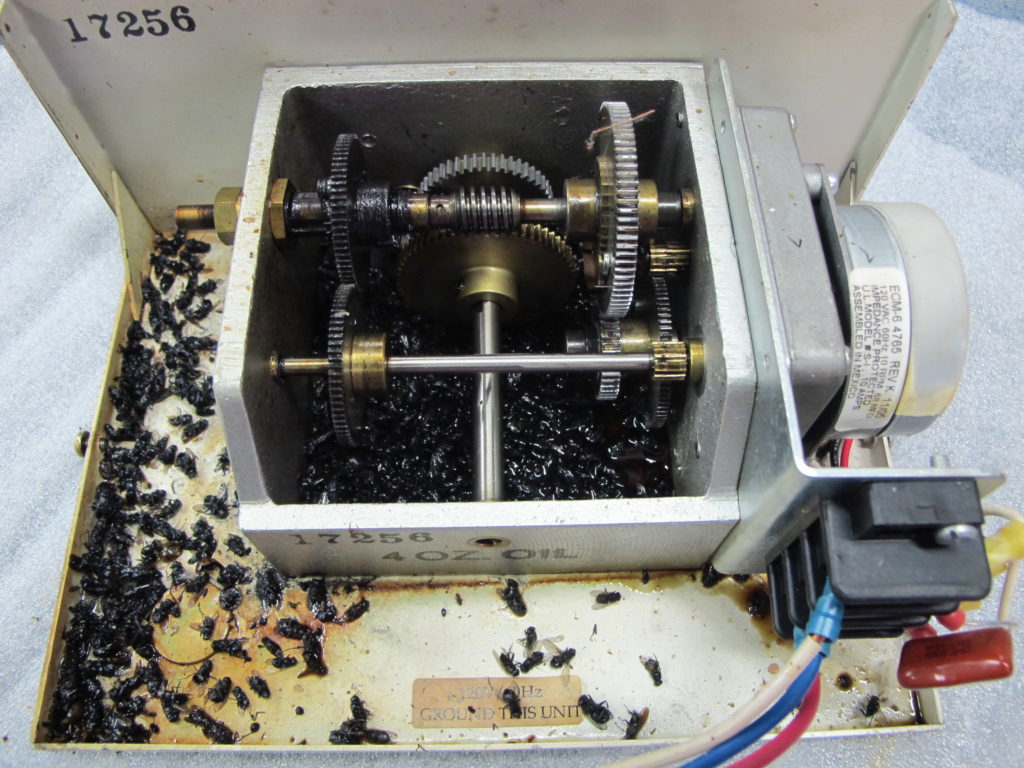

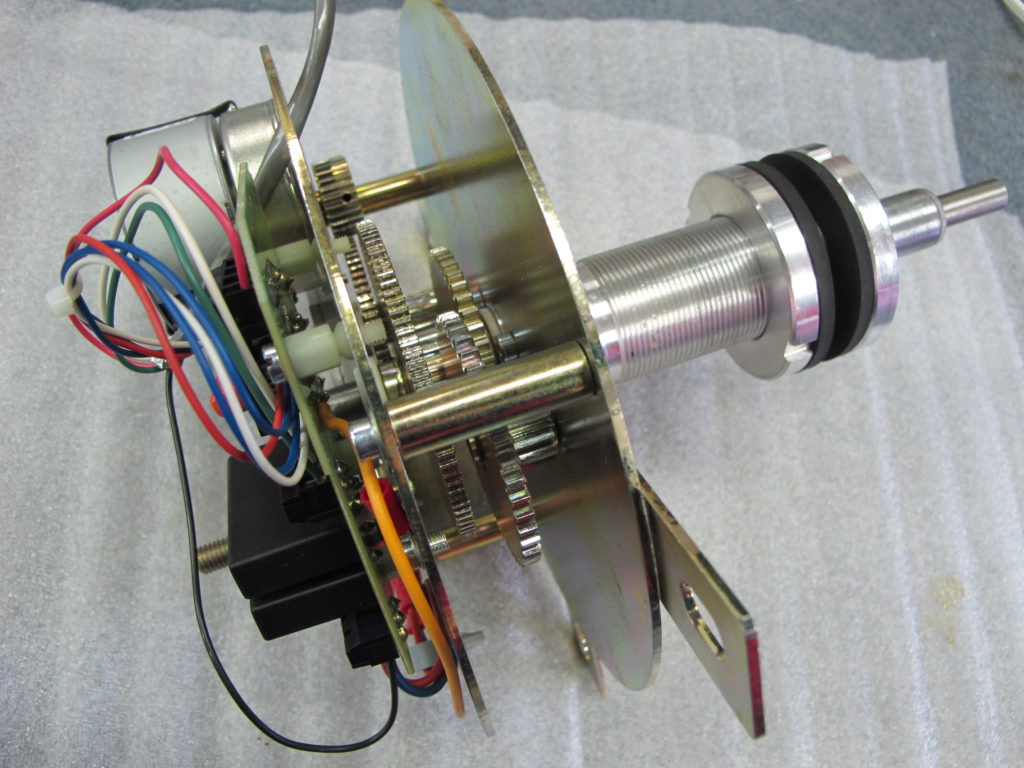

1) A set of lubrication-free heavy-duty impulse-drive clock movements – meaning the gears are all plated and require no oil, and the stainless steel shafts are all running through nylon bearing sleeves for maintenance-free operation. The movement actually ‘ticks’ on impulse from the master clock controller, for about 3 seconds, once a minute. Unlike the old movements which were continuously operated 120v electric motors, the new units run for a fraction of the time (5% for those who appreciate the math).

Master Clock Controller

2) All three of the clock movements are controlled by one master clock controller located inside the clock tower room, synchronized by a GPS antenna. The master clock automatically keepstrack of the time and will reset the display clocks after power interruptions and Daylight Saving Time changes. It has a small lithium battery which stores the time when power is turned off and calculates the difference when power is restored to fast-forward the clocks.

GPS Antenna sychronizes to Atomic Time

The master clock is self-contained with a quartz crystal (like a battery powered watch) for the time-base. Unlike a watch, however, the crystal is kept exactly on-time daily by means of a GPS antenna which we built-in to one of the clocks behind the dial. The antenna gets a signal from ‘space’, sort of like a pulse, which keeps it from ‘drifting’ which can happen with any quartz time-base, especially with temperature fluctuations, such as in a non-temperature controlled room in a clock tower.

LED dial illumination

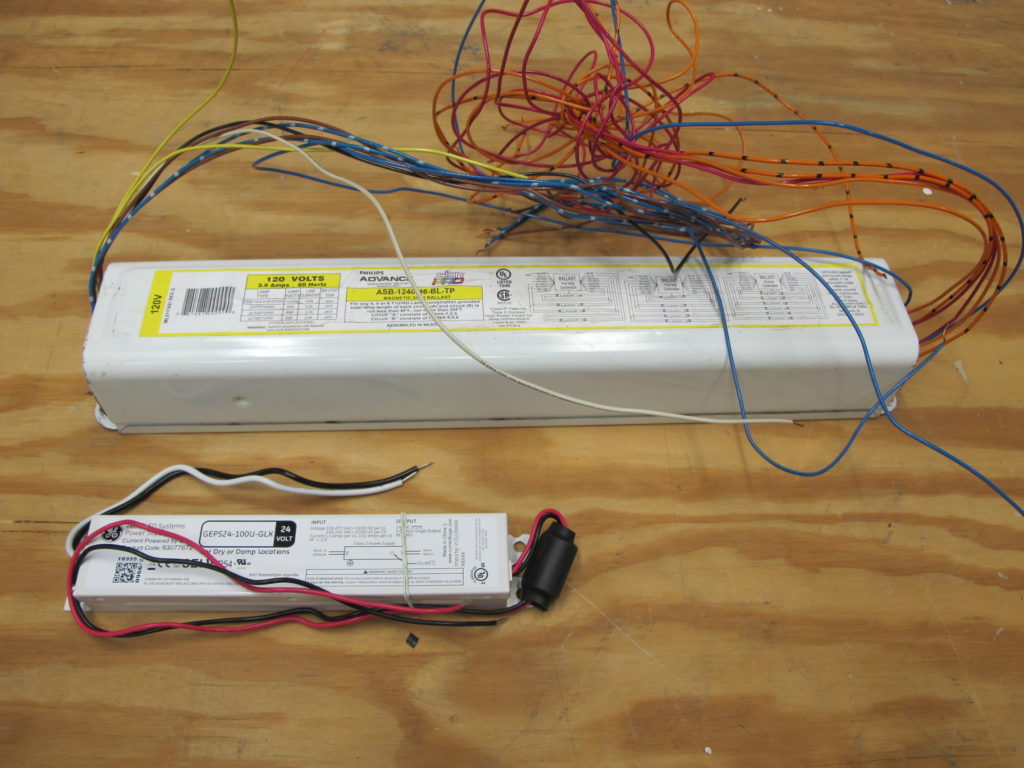

3) LED illumination. What a difference! Compare the old system of florescent bulbs, enormous ballasts with a complete mess of wires to the new simple system. One key issue with the old clocks was changing the bulbs – it required the face to be removed. First the hands are removed, then the center-nut, then the outside retainer ring. The original was caulked-in around the perimeter — Not exactly service friendly. Lumichron builds clocks like these with rear butterfly doors for easy access in the event of any service required.

Another great attribute to LED lighting is the waterproof nature of the modules – IP 66 wet-rated plus 100,000 hour warranty – about 22 years with an average of 12 hours on/off. We located the LED power supplies (no longer called ‘transformers’) inside the clock tower room for easy change-out in the event of failure. There are many, many different brands of LED’s, but we have chosen to stick with GE – a quality name-brand which can be found easily through a sign-supply vendor. Now with 24v, they’re even more efficient.

On Site Service and Installation

Installation was pretty straight-forward despite the miserable weather – November in Michigan … on a boom-lift, disassembly, clearing out all the old florescent tubes, fixtures and related matter, installing the LED’s on a panel, with the movement attached, was fairly straight forward and clean. It shows how important communication and fore-thought is when designing clocks/clock towers.

New Clock Hands

The old faces were installed with new hands (due to the bushing size difference and faded paint), plus the new hands feature Architectural grade powder coating in Jet Black so the finish should last a really long time.

Synchronize

Final cleaning and sealing around the edge to the building and we left the clocks ticking in exact synchronization with NIST, thanks to the GPS antenna.

Three 5’ clocks, two men, two days and everybody was very happy…